carbonauten Poland Sp.Z.o.o is the licensee and exclusive producer of industrial pyrolysis plants for carbonauten GmbH Germany.

CO2 sink

Pyrolysis plants convert woody biomass residues into biochar, pyrolysis oil, and syngas. Because biochar is environmentally stable and remains stable for thousands of years, they are a scientifically recognized CO2 sink, as one ton of carbon corresponds to the physical equivalent of up to 3.67 tons of CO2.

Unique Technology

Carbonauten GmbH’s pyrolysis plants are designed for maximum yield from woody biomass residues, industrial robustness, reliable 24/7/360 continuous operation, low CAPEX and OPEX, control of process parameters, controlled cooling of the biochar, material utilization of the condensed pyrolysis oils, and high thermal performance.

The pyrolysis plants are proprietary developments of carbonauten GmbH. They are based on 23 years of experience in biomass cogeneration plants and the carbonization of woody biomass residues.

Industrial Size

Carbonauten Poland Sp.Z.o.o. manufactures the second-generation pyrolysis plant, which has a capacity of approximately 5,000 tons of dry biochar, 5,000 tons of pyrolysis oils, and 3 MW of thermal power. A decentralized factory operated by carbonauten GmbH always consists of several pyrolysis modules and, depending on its size, can produce at least 10,000 tons of biochar (30,000 tons of CO2 equivalent), 10,000 tons of pyrolysis oils, and 50,000 MWh of heat annually.

Specialized Experts

The team at carbonauten Poland Sp.Z.o.o. is responsible for the production, shipping, installation, and maintenance of the pyrolysis plants. They also train the production staff at carbonauten’s international „zero CO2 factories.“

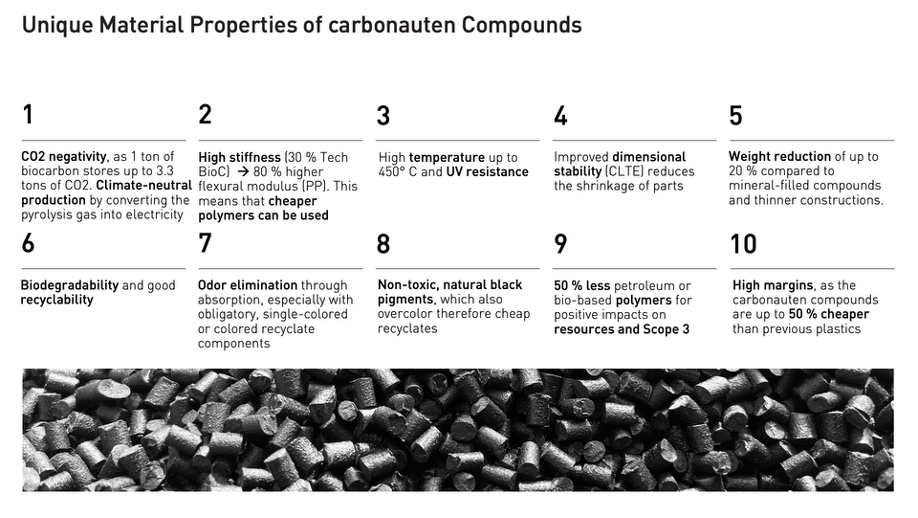

CO2-negative plastic compounds

carbonauten Poland Sp.Z.o.o also develops and produces biocarbon-filled compounds for the Polish plastics industry. These CO2-negative plastic granules belong to the „carbonauten NET Materials®“ (Negative Emission Technology) family. The 30–50% technical biocarbon content creates measurable CO2 sinks, improves properties, significantly reduces Scope 3 emissions, and lowers prices. Furthermore, they are produced in a climate-neutral manner in „zero CO2 factories.“

All this makes carbonauten compounds unique.

Example of a CO2-negative seat shell for the ICE of DB Deutsche Bahn

Waste wood from the DB was carbonized, the biochar was compounded with conventional polypropylene (PP) and injection-molded into a seat shell for the ICE.

This meant that DB incurred no costs for the disposal of the waste wood, and the CO2 emissions from its combustion were also avoided. The relatively simple plastic PP received significantly improved properties thanks to the almost 30% content of technical biochar.

With a net weight of 1.3 kg, the CO2 balance is negative at around -1 kg CO2 (Arburg calculation).

Welcome to the team!

The working atmosphere is characterized by high motivation thanks to meaningful work, a focus on quality, professional and friendly interaction, strong teamwork, a culture of error that promotes innovation, individual decision-making, and excellent compensation. The team looks forward to receiving your application. Please click here.

Imprint

carbonauten Poland Sp.Z.o.o

Mazowiecka 10

00-048 Warszawa

eMail info@carbonauten-poland.com

Managing Directors Torsten Becker, Christoph Hiemer